Product Description

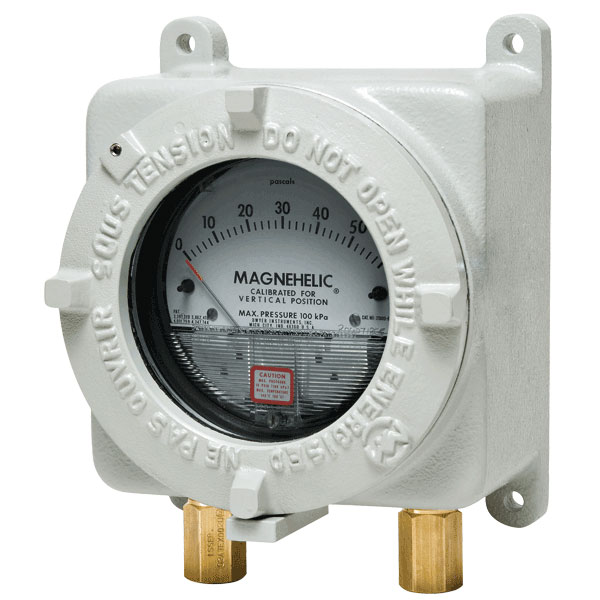

Magnehelic® Gage in Flame-Proof ATEX Enclosure

The popular Magnehelic® Differential Pressure Gage is now available in a flame-proof ATEX enclosure with the new ATEX approved AT22000 Series. This gage can indicate positive, negative or differential pressures and is accurate within 2%. The Magnehelic® gage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. Optional gage construction is available for use to either 35 psig (2.42 bar) or 80 psig (5.51 bar). Flame-proof ATEX enclosures are available in aluminum and include a glass window for viewing process pressures status on gage face.

Important notes for installation:

- Cables must be fitted through 1/2″ NPT cable gland or ATEX conduit (not supplied with instrument).

- Make sure after cabling to close tight cover and cable gland, in order to keep IP66 rating (IP65 with option OPV, overpressure relief valve).

- Open cover only after de-energizing instrument.

- Attention: Check local safety rules and warnings on unit and manual for a correct use of the instrument in hazardous area.

Please see SERIES 2000 for non-ATEX approved.

Product Applications

- Fan and blower pressures

- Filter resistance

- Air velocity

- Furnace draft

- Liquid levels with bubbler systems

- Pressure in fluid amplifier or fluidic systems